Lummel develop classic metal roofing techniques which combine craftsmanship and industrial perfection. This synthesis provides clients and architects with the greatest possible creativity.

Lummel works with all available materials, including:

- Aluminium

- Copper

- Titanium-zinc

- Stainless steel

- Titanium

Our product portfolio includes:

- Roofing

- Facades

- Stainless Steel – flat roof

- Conservation

- Internal cladding

- Customisation

- Metal forming

Roof cladding projects

Lummel can apply their craftsmanship and years of experience to a range of roof cladding projects of any type and material.

Single and double facades

We can install facades in single (non-ventilated) and double (ventilated) layer versions using different materials. These facades have been installed by Lummel for many years and are constantly incorporating newly developed ideas and construction methods.

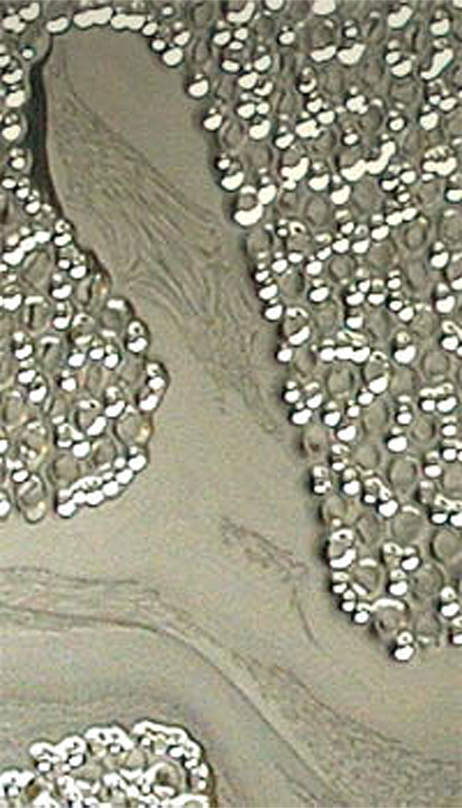

Stainless-steel flat roof renovation and installation

Lummel is able to find material-saving and durable solutions for renovation or new installation of flat roofs by using new technologies. Lummel builds and refurbishes flat roofs with zero degrees slope with continuously welded stainless steel. This type of system is very suitable for “cube” architecture, such as schools.

Compared to other materials stainless steel only offers a reliable long-term protection.

Benefits of using stainless-steel flat roofs include:

- A lifespan of 80-120 years

- Maintenance-free

- Low weight

- Heat reflection

- Suitable for 0° roof

- Algae and root-proof

- Improved fire behaviour

- Effortless lightning conduction

- No disposal of existing roof during refurbishment

Metal roofing conservation and renovation work

Lummel also takes part in the conservation and renovation of metal roofing on old buildings. Employing skills which have otherwise been lost to the mists of antiquity, Lummel has years of proven experience in conservation work. All of our metal cladding material is fully recyclable for use by future generations.

Internal cladding with classic materials

The combination of different materials opens up all creative possibilities for the design of enclosed rooms. To this end, Lummel uses classic materials such as copper and stainless steel, together with organic and modern elements to turn your imagination into reality.

Customised parts, individual solutions

Lummel can also supply specialised fabrication and custom build products – a challange we face with pleasure.

Sheet metal processing

In February 2003 we integrated punch, nibble and bench break facilities in addition to our classic range of works. With this new equipment we can open up an exciting new range of possibilities to our clients.