The Dutch Wind Wheel is an innovative and sustainable development concept proposed in the city of Rotterdam in the Netherlands. It comprises residential, hotel, dining and tourism facilities in addition to a clean-energy generating mechanism that highlights the Dutch clean technology and innovation in renewable energy.

The project is a collaborative effort from, Doepel Strijkers Architects, technology development firm BLOC, and leisure destinations development firm Meysters. Dutch Windwheel Corporation, a consortium formed by the three companies, initiated the project.

NBTC Holland Marketing is a partner in the project, while more marketing organisations, development companies, investors and government agencies are being sought to form an alliance for the implementation of the project.

The Dutch Wind Wheel is expected to attract 1.5 million tourists a year and is touted to become an architectural landmark and a major tourist attraction for the biggest port city of Europe.

Design and structure of the Dutch Wind Wheel

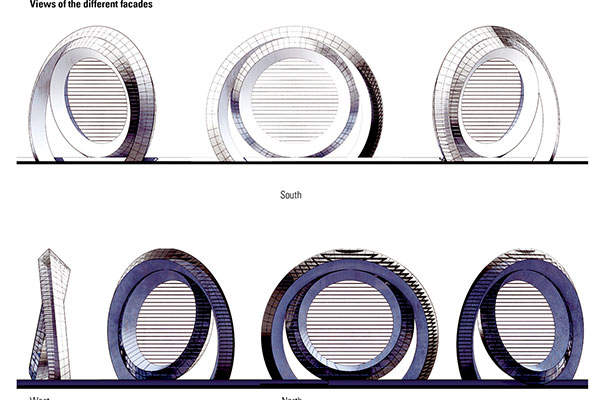

The Wind Wheel appears similar to a wind turbine, consisting of two three-dimensional (3D) rings with a light, open steel and glass construction. Its underwater foundation lends an illusion of a floating wheel.

The 174m (571ft)-tall structure comprises two rings or wheels that are coiled around each other and merge at the top. The rings are designed based on the principle of triangulation to achieve structural stability.

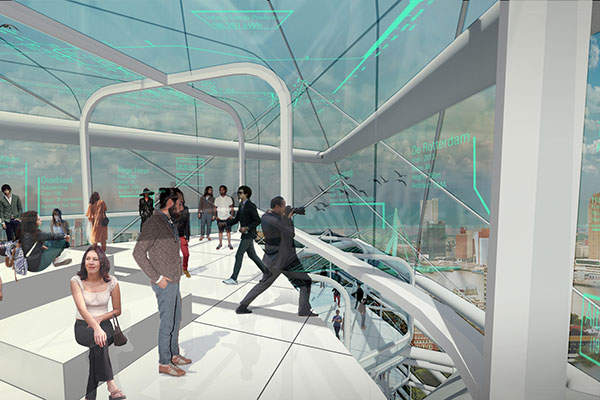

Forty rotating cabins on rails feature on the perimeter of the outer ring. These form a giant roller coaster, which provides visitors with mesmerising views of Rotterdam and its surrounding areas, including Europe’s biggest port, the Second Maasvlakte, and the sea.

The inner ring is designed to be an unconventional windmill that functions as a silent and motionless wind turbine converting wind energy into electricity using a framework of steel tubes.

The Dutch Wind Wheel features

The inner ring features a panorama restaurant, a sky lobby, a 160-room hotel on seven floors, 72 apartments and an interactive cinema. Commercial facilities are located at the plinth level of the inner ring.

Circular elevators and staircases are provided in the structural core of the wheel, while a parking space of 1,000 cars is located at the base.

The Dutch Wind Wheel also reduces the travel time to Kinderdijk, a UNESCO World Heritage site where 19 mills dating back to the 18th century are located, by 25 minutes on a fast ferry.

An interactive cinema in the 3D roller coaster takes the riders through the Dutch water management history. The cabin interiors of the giant coaster feature an innovative lighting concept.

Façade of the sustainable mixed-use development

The two three-dimensional rings are made of glass and steel, which lend the Dutch Wind Wheel a reflective appearance. A part of the Wind Wheel’s façade integrates digitally glazed ‘smart walls’, which display additional information to the visitors acting as a virtual information layer.

Technology used

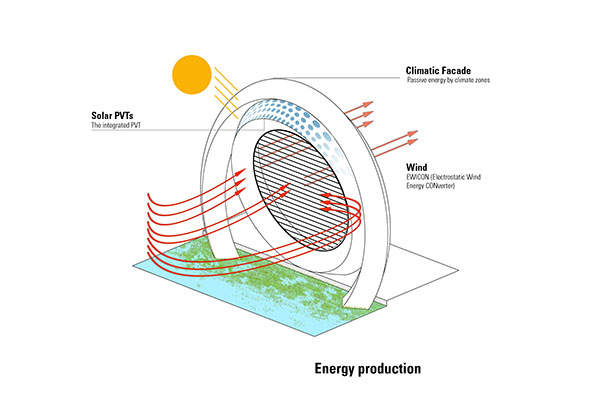

The windmill showcases an innovative technology called electrostatic wind energy converter (EWICON), which was created by Delft University of Technology and Wageningen University.

The bladeless wind turbine technology eliminates the need for any moving mechanical parts to produce electricity from wind energy. It uses insulated tubes (cables) in a steel framework that are fitted with electrodes and nozzles, which electro-spray positively-charged water into the air.

The electrical energy of the positively charged particles reaching the negative electrode increases when wind pushes them away. The enhanced electrical energy is captured in a battery. The entire system is cheaper to maintain and causes less wear because of the absence of moving mechanical parts.

Sustainability features of the Dutch Wind Wheel

The innovative windmill creates no noise and no moving shadows. The Wind Wheel is fitted with photovoltaic thermal hybrid solar collectors (PVTs) and features a climatic façade.

It also integrates an efficient water management system, which captures and uses rain water either inside the facility or store it in a wetland. Biogas is produced by collecting the organic waste from the building.

The entire structure is designed to be disassembled and re-used. Local material from the Rotterdam region, the harbour and the surrounding steel industry is proposed be used to build the structure.