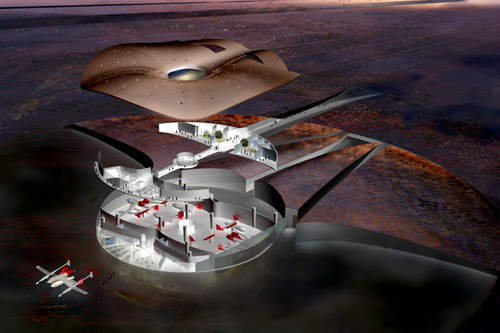

Mirroring the contours of the desert landscape, this sleek, unobtrusive structure – specifically designed to be ‘invisible’ at eye-level – will house the world’s first suborbital spaceport. Looking like something out of a Star Trek film, these cutting-edge designs represent the latest step in the race to deliver commercial spaceflights at an affordable price.

Situated in the nondescript New Mexican desert, on an 18,000-acre site, Spaceport America will be home to Virgin Galactic, among other space companies, with its fleet of five spaceships, with tickets set to be available for $200,000 from 2013.

Unveiled in the summer of 2007, the designs from Foster & Partners are the result of a process begun in the early 1990s, when the Southwest Space Task Force located 27 square miles of state-owned land, 45 miles north of Las Cruces in New Mexico, with the aim of constructing an inland spaceport.

Cabinet Secretary Rick Homans then petitioned Governor Bill Richardson with the idea, resulting in legislation to finance the project and a design competition involving 11 tenders.

Foster & Partners, in partnership with engineering design firm URS Corp, have designed the 103,000ft² (9,569m²) hangar and terminal facility to be appreciated from the air – a low-lying structure with a rolling, concrete roof resembling a manta ray.

The facility will house Virgin Galactic’s offices and hangar space, about 84,000ft² (7,803m²), on a 20-year lease, and will also provide the headquarters of the NMSA. The Rocket Racing League, Starchaser Industries, UP Aerospace and the X Prize Cup are also likely residents.

Spaceport America will also be the development and launch site for a suborbital vehicle developed by Armadillo and Rocket Racing League.

Virgin Galactic

The enterprise consists of two transport airplanes and five spaceships, designed by Burt Rutan, the award-winning designer of SpaceShipOne. A transport plane, known as a White Knight 2, carries a spaceship to an altitude of 49,000ft.

The vehicle, SpaceShipTwo, then launches into suborbital space, reaching 84 miles above the planet before returning two and a half hours later. The spaceships are under construction at Scaled Composites in Mojave, California. The commercial flights will be available only after the Spaceport’s completion in March 2013.

As well as hanger space for the planes and spaceships, the building will house pre and post-flight training facilities, mission control, viewing galleries and passenger lounges.

Also on site will be customer services, medical facilities, sleeping quarters for astronauts, a staff clubhouse and offices for up to 200 personnel.

Entrance to the building is via a deep channel, hidden from view in the landscape, with high surrounding walls on which historic information about the region and space exploration will be exhibited. Visitors then proceed to a superhanger where the spacecraft and simulation room are located, and the terminal building.

The terminal hall has a glazed façade, 50ft ceilings and massive windows overlooking the main runway on the spaceport’s eastern side, where visitors can watch the spacecraft take off.

Environmentally friendly

The spaceport has been designed to meet sustainable and environmental criteria laid out by the client – the State of New Mexico, through the NMSA (New Mexico Spaceport Authority). The NMSA is keen to use local materials and construction techniques, and is providing $100m.

The state also required the facility to be sensitive to the nearby El Camino Rael de Tierra Adentro Trail, along with the two ranches located on the same leasehold, as well as conform to the ‘green building guidelines’ as defined by PCD (property control division).

According to RFP (request for proposals) 70-350-441999-02 published in April 2007, the structure should ‘integrate building materials and methods that promote environmental quality, economic vitality and social benefit’, achieving the minimum of a gold LEED rating.

The structure harmonises with the undulating curves of the landscape, taking advantage of the planet’s thermal mass, which protects it from heat and climatic conditions, as well as using winds for ventilation. Heating, cooling and lighting are generated via passive energy, while electricity is generated via photovoltaic panels.

There are skylights to admit light during the day and water is recycled from the roof. The spaceport is designed to have minimal embodied carbon requirements and qualifies for a coveted LEED platinum accreditation.

Spaceport America contractors

SMPC Architects, PHA Consult, Balis and Company and Exploration-Synthesis Partners have been involved to tackle issues such as security and privacy.

DMJM:AECOM are the contractors for architectural and engineering aspects of the site, such as roadways, runway, security, water, power and communication systems. Design consultants Dekker Perich Sabatini and Molzen-Corbin & Associates are also collaborating on the project.

Spaceport progress

In September 2008 the New Mexico Department of Transportation (NMDOT) broke ground on road improvements on the county road A013 from Engle in New Mexico to the junction between the AO13 and the AO39, which is where the entrance to Spaceport America will be situated. The construction work was undertaken by Reiman Construction.

At the spaceport tax referendum, Dona Ana County and Sierra County approved a 0.25% increase in gross receipts taxes to support the spaceport’s construction. Otero County rejected the proposal in 2008.

The NMSA launch site operator licence application was submitted to the FAA on 2 July 2008, and following review by the FAA’s associate administrator for commercial space transportation (FAA/AST), the site licence was issued for vertical launches in December 2008. The construction began upon the completion of the environmental impact statement (EIS) and record of decision (ROD) process.

A 10,000ft long runway was opened in October 2010. As of October 2011, the launch pad was completed and terminal building construction was put on hold.

Gerald Martin Construction Management of Albuquerque was chosen as the construction manager of the spaceport on behalf of NMSA in December 2008. HDR is providing the construction management services.

CMC Construction is the contractor for the interior roads of the Spaceport America site. FNF New Mexico is the general contractor for road works. David Montoya Construction was the runway contractor.

McDade-Woodcock is the electrical works contractor. Smithco is the contractor for water storage tank, utilities and booster pump station at the site. Engineering System Solutions (ES2) is the designer and engineer for the ARFF facility, structural system and insulated concrete shell for the building.

Bateman-Hall is the contractor for the air rescue fire fighting facility at the site. There will be six miles of asphalt paved internal roads on the site and seven miles of unpaved road.

Sierra Electric Co-op of Elephant Butte, NM (designers) procured construction and installation services for off-site power distribution (25kV switching and distribution system and 115kV transmission line and substation) to supply the spaceport.

The vertical launch of the UP Aerospace vehicle SL-3 (this was due to be carried out in June 2008 but the launch was delayed). The launch of UP Aerospace SpaceLoft XL rocket for the SL-3 Education launch on 2 May 2009 was 62 miles short of reaching the desired altitude. The previous four successful launches from the site included SpaceLoft XL on 28 April 2007.

The groundbreaking event of permanent facilities was held on 18-19 June 2009, followed by bid packages for the spaceport wastewater, water and fuel storage systems.

According to Virgin Galactic, more than 45,000 people have registered as potential astronauts. A double-hulled mother ship, WhiteKnightTwo, will carry a piloted six-passenger capsule to an altitude of 48,000ft. The released capsule will rocket on into space for four minutes of free floating before gliding back to New Mexico.