London Aquatics Centre (LAC), which played host to the London Olympics 2012, with its two swimming pools and a diving pool, was opened for public use in March 2014. The temporary attached structures to the building, built specifically to accommodate 17,500 spectators for the event, were removed and major modifications were made to the building.

The LAC is located at the entrance to the south of Queen Elizabeth Olympic Park, providing direct access to the Stratford City Bridge. GLL, a charitable social enterprise, operates the building on behalf of London Legacy Development Corporation.

The building is now fitted with glass on both sides, the area where the two seating stands were located. The building now provides a total seating capacity of 2,500, which is expandable to 3,500 by adding temporary seats.

A former life as an Olympic swimming centre

Construction works on the London Aquatic Centre began in July 2008 and the building was completed in July 2011, in time for the games. The preconstruction works included the demolition of 11 industrial buildings and use of 140,000t of soil sourced from outside the project site.

The building was constructed with an investment of £225m ($371m approximately). Up to £34m ($56m) was provided by Sport England through the National Lottery funding. A further £5m ($8m) was provided by Sport England, which enabled the transformation of the venue into a public space.

The transformation project for the London Aquatics Centre from the Olympic mode to its present legacy mode was carried out as part of a larger £292m ($481m) project being implemented in phases to transform the Olympic Park into a new public park.

Design and details of London Aquatics Centre

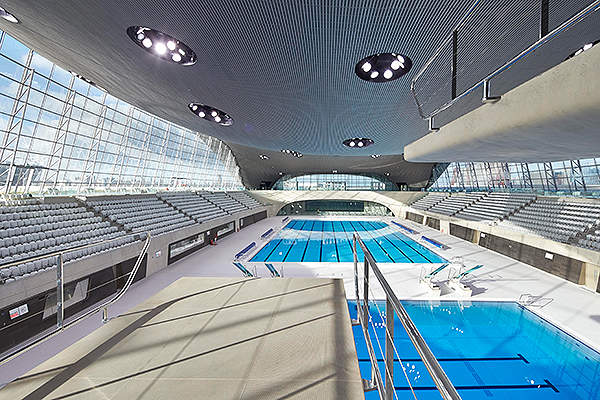

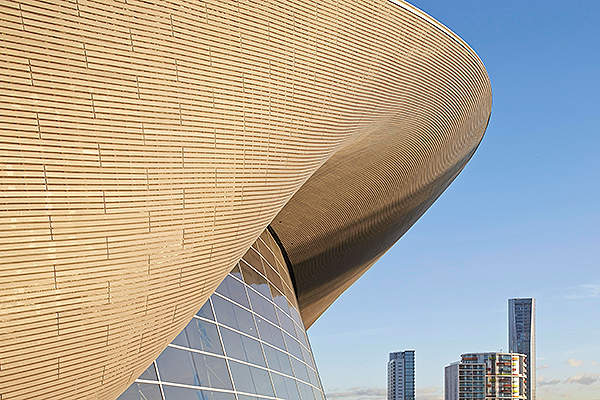

The main attraction of the building, designed by Zaha Hadid Architects initially for the client Olympic Delivery Authority, is its wave-like ceiling which emanates from the ground and supported by three concrete structures, two structures at the northwest end and a single structure at the south east end.

The roof is 160m long, approximately 80m wide, weighs 3,000t, and was constructed using aluminium, 2,800t of structural steel, and 70,000 bolts. The components of the roof are 50% recyclable and the ceiling is fitted with sustainable timber.

The building is 45m high and contains 600,000 tiles. The gross floor area of the building is 20,264m², the basement of the building covers an area of 3,725m², while the ground floor and the first floor cover 15,137m² and 10,168m² respectively.

The three insulated pools with movable floors and walls contain 10 million litres of water and are lined with 180,000 tiles. The competition pool is 50m long and three metres deep and features 10 lanes. The training pool is also 50m long and features eight lanes, while the diving pool is 25m in length. The building features six diving platforms, with the highest tower rising at a height of 10m.

The building is fitted with 314 panes of blast resistant glass on each side, covering a total area of 2,800m². The glasses are screen printed with dot matrix pattern and vary in size and pattern, to control daylight levels and restrict glare. Hot water runs through the steel framework to prevent condensation on the glass.

Facilities at the LAC

New facilities include a cafe, changing facilities, a creche, meeting rooms, a sports science space, a concourse, pre-swim shower facilities, and a lift system called Poolpod meant for people who require mobility assistance. The building serves as a training area for dry diving, lane swimming, aqua-aerobics, water polo and synchronised swimming.

The gym within the building is fitted with equipments supplied by Technogym. The building also features a dry-land training facility equipped with trampoline, springboards, foam pits and harness.

Sustainability features of London Aquatics Centre

The building uses 32% lesser potable water compared to other pools, by using low flow fittings and recycling water. The building’s air conditioning system uses ammonia chillers. The building is also connected to the Queen Elizabeth Olympic Park’s district heating and power system, which uses a combination of biomass boilers and a combined heat and power (CHP) plant.

Secondary aggregates and cement were used to reduce the concrete usage in the building. The project was specially accredited with BREEAM Innovation Credit for the concrete mixes used.

The main pool hall is naturally lit throughout and the design incorporated rainwater harvesting. The harvested water is used to irrigate the green wall at the southern end of the building. The temporary construction materials used in the Olympic mode are either being recycled or re-erected in other locations.

Contractors involved

The main contractor for the building was Balfour Beatty, while Arup acted as the structural engineer and the mechanical and electrical (M&E) engineers. The facade engineer was Robert-Jan Van Santen Associates and the steel work contractor was Rowecord Engineering.

The glass used for the building was manufactured by Seele at Leon, North West Spain. The waterproof door systems within the building were supplied by Dortek. The water treatment and water feature systems for the building were designed and installed by Devin Consulting.