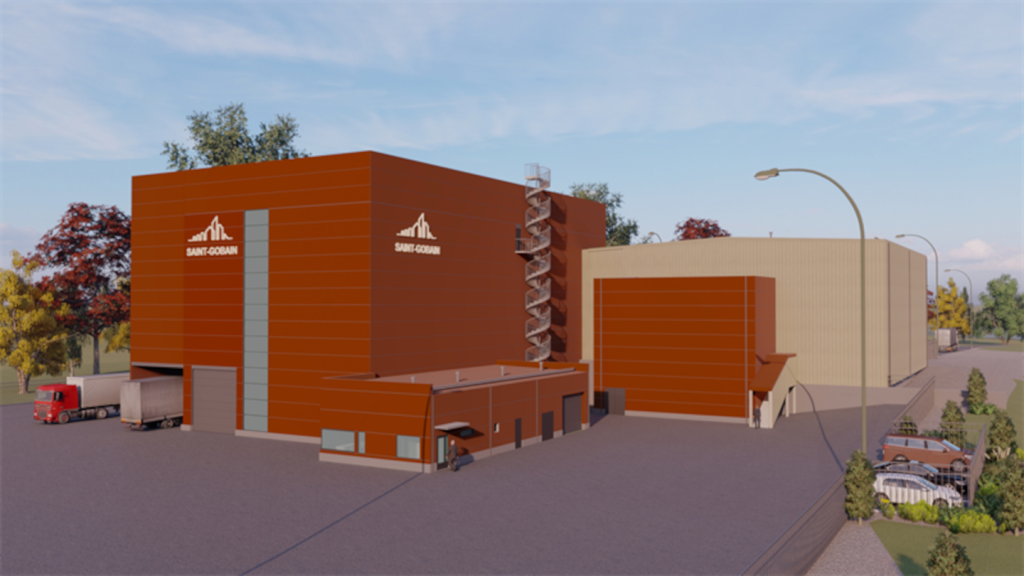

The construction of a new steel ladle slag plant by Saint-Gobain in Raahe, Finland is currently underway, marking a significant step towards sustainable construction materials.

The facility, set to be completed in 2025, will transform steel slag into low-carbon binders, offering an eco-friendly alternative to traditional cements.

Saint-Gobain and SSAB are collaborating on a project to establish a circular economy in the construction sector.

Through this venture, steelmaking by-products will be converted into low-carbon binders for use in Saint-Gobain Weber's dry mortars, significantly reducing the carbon footprint of these materials by up to 90%.

SSAB By-product sales and development director Marko Mäkikyrö said: “This project supports our ambition to be a leader in responsible steelmaking. SSAB has taken a policy decision to transform all its production sites to fossil-free steelmaking. Already at this stage, it is important to ensure that also future by-products are utilized as efficiently as possible and this project is a part of this development.”

This process, a first in the world, will allow for the complete recycling of slag from SSAB's steel production.

The five-year joint development effort by the two companies aims to utilise 100% of the slag, ensuring no waste is generated.

The slag processing plant is designed to sort and process slag, recovering metals to be reused in SSAB's manufacturing, while the remaining material will be transformed into alternative binders for Saint-Gobain's use.

Saint-Gobain's has committed to an investment of approximately €12m ($13.2m) in the Raahe Harbor area facility and related processes. This aligns with the company's goal of achieving net-zero carbon emissions in Finland by 2025 and globally by 2050.

SSAB's contribution to the project is around €2m.

The joint initiative has garnered financial support, receiving funding of about 35% from the Sustainable Growth Programme for Finland, which is part of the NextGeneration EU initiative.

In 2022, Saint-Gobain took a further step by filing a patent for the use of slag powder as a binder.

Saint-Gobain Finland senior R&D manager Gunnar Lauren said: “The process will enable us to reduce more than 20,000 tonnes of carbon dioxide emissions a year. The use of virgin materials will decrease and the use of domestically manufactured raw materials increase.”