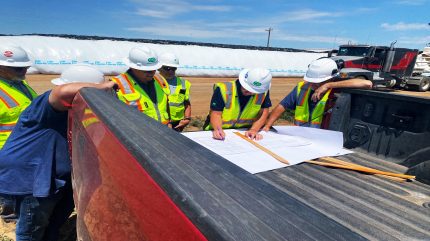

Ground has been broken on Clean Energy Fuels’ renewable natural gas (RNG) production plant at South Fork Dairy in Dimmitt, Texas, US.

South Fork Dairy houses a herd of 16,000 cows.

Once operational, the new RNG facility is poised to be one of the largest of its kind in the US, with an annual RNG production capacity of approximately 2.6 million gallons.

This sustainable transportation fuel, derived from organic waste, will be integrated into Clean Energy’s network of fuelling stations across the country.

With an estimated cost of approximately $85m, the construction of the digesters and processing plant is set for completion in 2025.

Agriculture contributes to nearly 10% of US greenhouse gas emissions, as reported by the US Environmental Protection Agency.

RNG production, by capturing methane from farm waste, offers a significant reduction in these emissions.

The California Air Resources Board has recognised RNG from dairy farms as exceptionally clean, assigning it an average carbon-intensity score of -330, which is notably lower than the score for electric vehicles charged using the current electricity grid.

Clean Energy senior vice-president of renewables Clay Corbus: “Building anaerobic digesters at a large dairy [farm] like South Fork will help the dairy owner, Frank Brand, and his team collect and monetise sizeable amounts of manure waste while also benefiting from the environmental credits an RNG facility brings.”

Brand added: “The project not only helps us convert our waste into a clean, usable sustainable fuel, but it also helps us with managing manure which for a dairy of our size is quite a feat.

“We do this while simultaneously reducing our environmental footprint – it’s a direction I hope many other dairies will look to pursuing.”