Sumitomo Osaka Cement has been granted a patent for a ceramic composite sintered body that features a metal oxide as the main phase and silicon carbide as a sub-phase. The silicon carbide crystal grains comprise at least 25% of the total area ratio within the metal oxide matrix. GlobalData’s report on Sumitomo Osaka Cement gives a 360-degree view of the company including its patenting strategy. Buy the report here.

According to GlobalData’s company profile on Sumitomo Osaka Cement, Electrode active materials was a key innovation area identified from patents. Sumitomo Osaka Cement's grant share as of July 2024 was 45%. Grant share is based on the ratio of number of grants to total number of patents.

Ceramic composite sintered body with silicon carbide and metal oxide

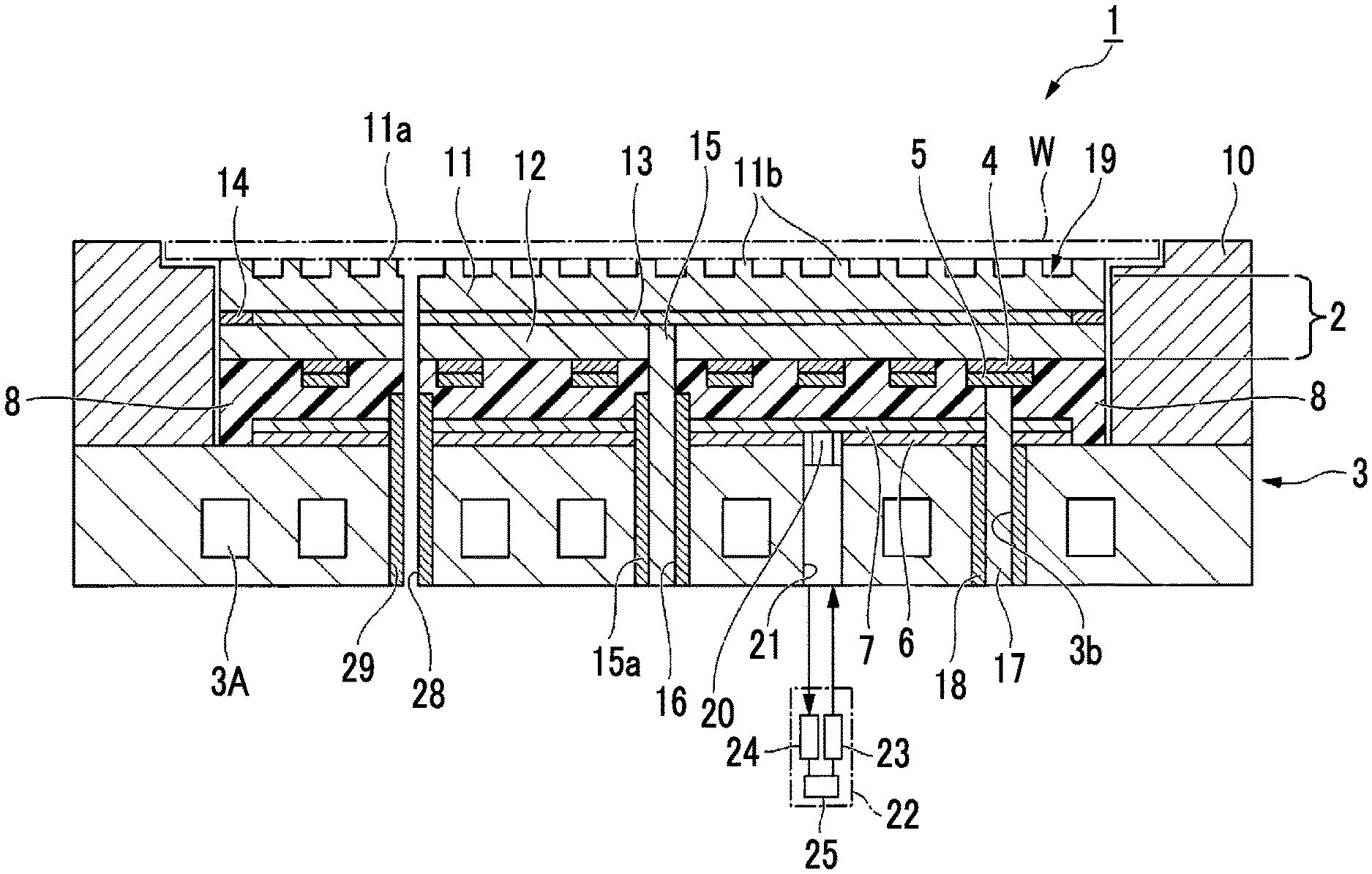

The granted patent US12074050B2 describes a composite sintered body that integrates a metal oxide as the main phase and silicon carbide as a sub-phase. The silicon carbide is characterized by its crystal grains being dispersed within the metal oxide's crystal grains and at the grain boundaries, with a minimum area ratio of 25% for the silicon carbide relative to the total crystal grains. The patent specifies that suitable metal oxides include aluminum oxide or yttrium oxide, and it outlines that the average crystal grain size of the metal oxide should range between 1.2 µm and 10 µm. Additionally, the patent details the construction of an electrostatic chuck member and device utilizing this composite sintered body, highlighting its application in holding plate-shaped samples through electrostatic attraction.

The patent also outlines a method for producing the composite sintered body, which involves several steps: mixing metal oxide and silicon carbide particles, adjusting the pH of the resulting slurry to ensure positive and negative surface charges on the respective particles, forming a body after removing the dispersion medium, and then pressure-sintering the formed body at temperatures of 1600°C or higher under a non-oxidative atmosphere. The method may include high-speed mixing of the particles and optional surface oxidation of the silicon carbide prior to mixing. The patent further specifies that the metal oxide content should be at least 99.99%, with the composite body containing a minimum of 92% by mass of metal oxide and 8% by mass of silicon carbide, which may include ß-SiC in a volume ratio of 4% to 15%.

To know more about GlobalData’s detailed insights on Sumitomo Osaka Cement, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.