Nippon Electric Glass’s patent involves a glass roll with a band-shaped glass film free of skew and slack when wound in a roll-to-roll mode. The film includes an effective section with specific measurements to ensure uniformity. The creases on the film’s surface create an even surface without cracks. GlobalData’s report on Nippon Electric Glass gives a 360-degree view of the company including its patenting strategy. Buy the report here.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

According to GlobalData’s company profile on Nippon Electric Glass, Hydrogen storage alloys was a key innovation area identified from patents. Nippon Electric Glass's grant share as of March 2024 was 35%. Grant share is based on the ratio of number of grants to total number of patents.

Uniform glass roll with minimal skew and slack

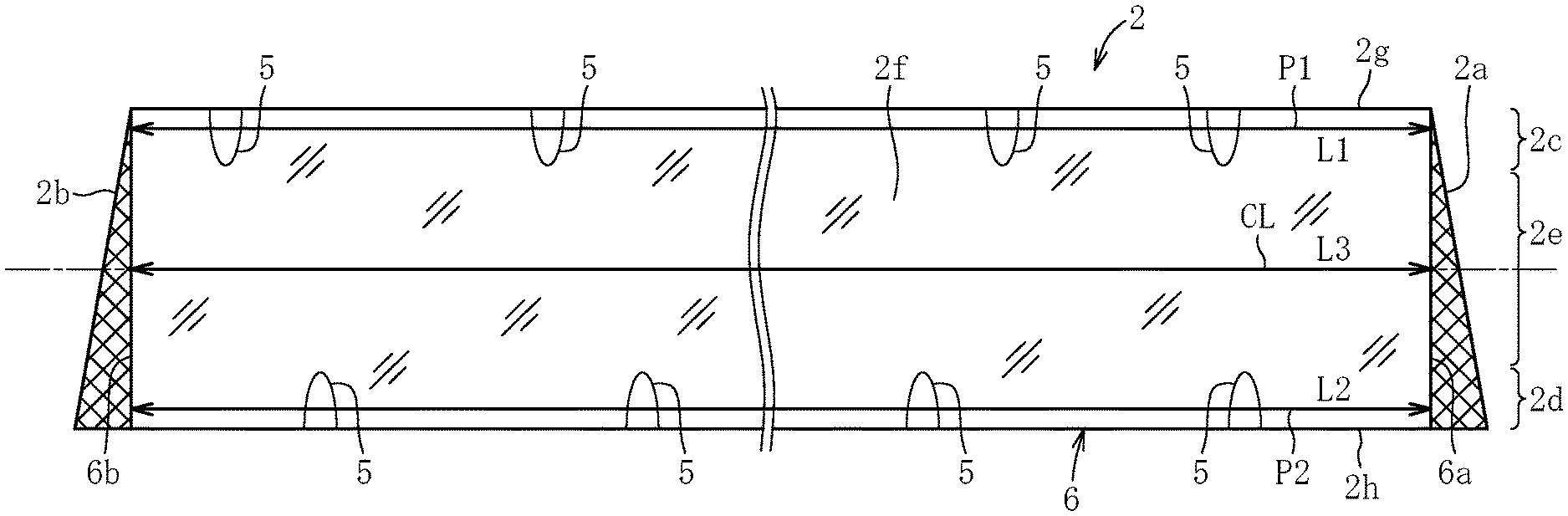

A recently granted patent (Publication Number: US11964894B2) discloses a glass roll comprising a band-shaped glass film with creases formed on it. The band-shaped glass film includes an effective section where the side edges and end portions extend parallel to each other. The patent specifies that the difference between certain lengths on the glass film should be 400 ppm or less of the longer length. The creases on the glass film create surface unevenness without cracks and are not eliminated with tension. Additionally, the patent details a glass roll manufacturing method involving cooling and solidifying a glass ribbon to obtain a band-shaped glass film with creases, dividing unnecessary portions, winding the effective portion into a roll shape, and measuring lengths along the width direction to ensure uniformity. The method includes adjusting cooling speeds to reduce length differences and discarding sections with excessive differences.

Furthermore, the patent outlines specific steps for adjusting cooling speeds to reduce length differences between measurements taken along the width direction of the glass film. The method involves alternately performing measurement and adjustment steps until the length differences meet specified criteria. Additionally, the patent describes the use of a rotating body in a measurement unit to measure lengths based on the surface irregularities caused by creases. The method also includes adjusting the cooling speeds using heating units for different parts of the glass ribbon. Overall, the patent aims to ensure the uniformity of the glass roll by controlling the formation of creases and maintaining consistent lengths across the width of the band-shaped glass film during the manufacturing process.

To know more about GlobalData’s detailed insights on Nippon Electric Glass, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.