Hatch has filed a patent for a process to refine ferronickel alloy and produce nickel sulfate or other nickel products. The process involves treating the alloy with an oxidizing leach, such as pressure oxidation or leach with peroxide or copper ions. The presence of added copper, like a copper sulfate solution, is also mentioned. The process includes steps to remove copper and iron, remove impurities, and either crystallize the nickel sulfate or produce another nickel product. GlobalData’s report on Hatch gives a 360-degree view of the company including its patenting strategy. Buy the report here.

According to GlobalData’s company profile on Hatch, extraction by leaching was a key innovation area identified from patents. Hatch's grant share as of June 2023 was 1%. Grant share is based on the ratio of number of grants to total number of patents.

Refining ferronickel alloy using oxidizing leach

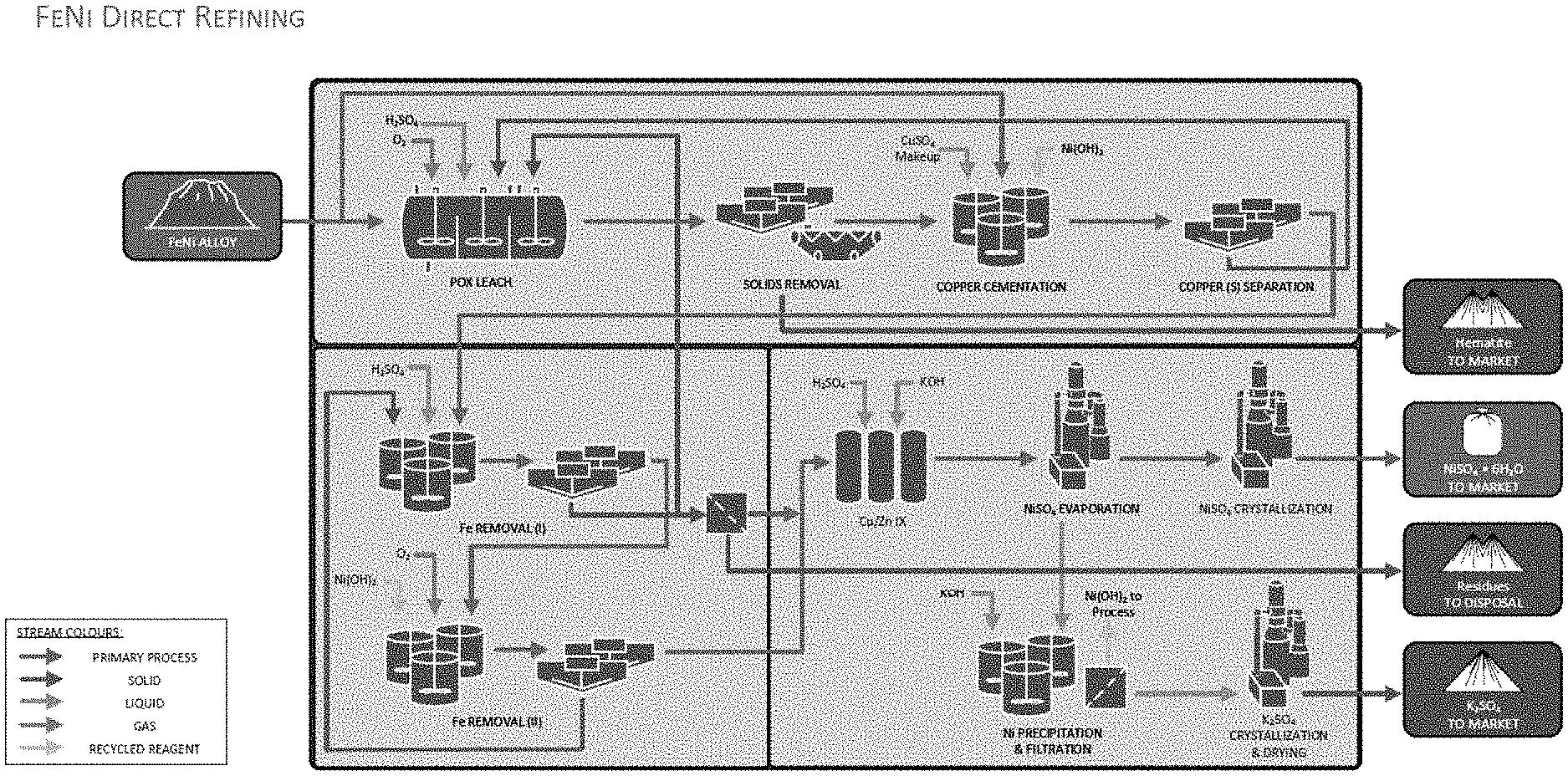

A recently filed patent (Publication Number: US20230193423A1) describes a process for refining ferronickel alloy. The process involves treating the ferronickel alloy with an oxidizing leach. This treatment can be done using various methods, such as pressure oxidation (POX) leach, treating the alloy in the presence of copper, peroxide, or sulfuric acid.

In one embodiment of the process, the ferronickel alloy is treated at atmospheric pressure in a vessel, such as a column. Another embodiment involves providing a peroxide treatment and a POX treatment. The peroxide treatment is done by treating the alloy in the presence of peroxide and sulfuric acid, which produces a discharge liquor. This discharge liquor is then treated with the POX.

The process also includes producing an iron product, such as hematite, jarosite, or goethite, from the ferronickel alloy. This is achieved by selectively removing iron in the form of hematite through pressure oxidation (POX) of the alloy.

If the ferronickel alloy is treated in the presence of copper, the process includes a copper recovery step. This step can involve various methods, such as solvent extraction, electrowinning, cementation, sulfidation, pH adjustment, ion exchange, or pressure oxidation. In one embodiment, a portion of the alloy or nickel powder is provided to cement the copper during the recovery step. At least a portion of the recovered copper can be returned upstream to the oxidizing leach treatment step or a pre-leach step.

The oxidizing leach in the process produces a discharge liquor containing uncrystallized metal sulfate. The process includes producing a nickel product by crystallizing the uncrystallized metal sulfate to form a crystallized nickel sulfate or a co-crystallized nickel and cobalt sulfate in a mother liquor. The crystallized nickel sulfate or co-crystallized nickel and cobalt sulfate can be separated from the mother liquor. The remaining uncrystallized metal sulfate in the mother liquor can be converted to a basic metal salt, which can be used upstream of the crystallization step.

Overall, this patent describes an improved method for refining ferronickel alloy, which involves various treatments and recovery steps to produce a nickel product. The process also includes the production of an iron product and the use of copper during leaching.

To know more about GlobalData’s detailed insights on Hatch, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.